Rantai Penggilingan Baja Las dan dengan Lampiran, Rantai Tarik Baja Las dan Lampiran

RANTAI PENGGILING BAJA YANG DILAS

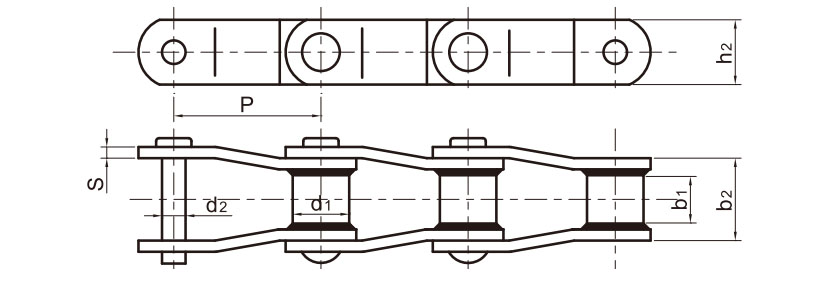

| GL Rantai TIDAK. | Melempar | Diameter Luar Laras. | Pin dia. | Kedalaman pelat | Perkiraan Muka Gigi pada Garis Pitch | Panjang Bantalan | Ketebalan Pelat | Kekuatan tarik pamungkas | Berat sekitar | |

| P | d1(maks) | d2(maks) | h2(maks) | b1(maks) | b2(maks) | S(maks) | Q | q | ||

| mm | mm | mm | mm | mm | mm | mm | kN | kg/kaki | kg/m | |

| WR-78 | 66.27 | 22.23 | 12.70 | 28.40 | 31,75 | 51.00 | 6.40 | 93.40 | 1,90 | 6.23 |

| WH-78 | 66.27 | 22.23 | 12.70 | 28.40 | 31,75 | 51.00 | 6.40 | 146,00 | 1,90 | 6.23 |

| WR-82 | 78.10 | 26,97 | 14.35 | 31.80 | 38.10 | 57.40 | 6.40 | 100.10 | 2.28 | 7.48 |

| WH-82 | 78.10 | 26,97 | 14.35 | 31.80 | 38.10 | 57.40 | 6.40 | 132,00 | 2.28 | 7.48 |

| WR-124 | 101.60 | 31,75 | 19.05 | 38.10 | 41.28 | 70.30 | 9.70 | 169,00 | 3.62 | 11,88 |

| WH-124 | 101.60 | 31,75 | 19.05 | 38.10 | 41.28 | 70.30 | 9.70 | 307,00 | 3.62 | 11,88 |

| WR-111 | 120,90 | 31,75 | 19.05 | 44.45 | 57.15 | 86.20 | 9.70 | 169,00 | 4.17 | 13.68 |

| WH-111 | 120,90 | 31,75 | 19.05 | 44.45 | 57.15 | 86.20 | 9.70 | 266,70 | 4.17 | 13.68 |

| WR-106 | 152.40 | 31,75 | 19.05 | 38.10 | 38.10 | 69,85 | 9.70 | 169,00 | 3.00 | 9.84 |

| WH-106 | 152.40 | 31,75 | 19.05 | 38.10 | 38.10 | 69,85 | 9.70 | 250,00 | 3.00 | 9.84 |

| WR-132 | 153,67 | 44.45 | 25.40 | 50.80 | 73,00 | 111.00 | 12.70 | 275,80 | 6.43 | 21.10 |

| WH-132 | 153,67 | 44.45 | 25.40 | 50.80 | 73,00 | 111.00 | 12.70 | 511,00 | 6.43 | 21.10 |

| WR-150 | 153,67 | 44.45 | 25.40 | 63.50 | 73,00 | 111.00 | 12.70 | 531,00 | 7.74 | 25.39 |

| WH-150 | 153,67 | 44.45 | 25.40 | 63.50 | 73,00 | 111.00 | 12.70 | 543,00 | 7.74 | 25.39 |

| WR-155 | 153,67 | 44.45 | 28.57 | 63.50 | 73,00 | 117.48 | 15,88 | 659,00 | jam 9.00 | 29.53 |

| WH-155 | 153,67 | 44.45 | 28.57 | 63.50 | 73,00 | 117.48 | 15,88 | 779,00 | jam 9.00 | 29.53 |

| WR-157 | 153,67 | 44.45 | 28.57 | 63.50 | 76.20 | 117.48 | 15,88 | 659,00 | 9.10 | 29.86 |

| WH-157 | 153,67 | 44.45 | 28.57 | 63.50 | 76.20 | 117.48 | 15,88 | 779,00 | 9.10 | 29.86 |

| WR-159 | 155.575 | 48.26 | 31,75 | 76.20 | 69,85 | 117.48 | 15,88 | 823,00 | 11.80 | 38.71 |

| WH-159 | 155.575 | 48.26 | 31,75 | 76.20 | 69,85 | 117.48 | 15,88 | 935,00 | 11.80 | 38.71 |

| WR-200 | 155.575 | 48.26 | 31,75 | 63.50 | 69,85 | 117.48 | 15,88 | 823,00 | pukul 10.00 | 32.81 |

| WH-200 | 155.575 | 48.26 | 31,75 | 63.50 | 69,85 | 117.48 | 15,88 | 84600 | pukul 10.00 | 32.81 |

| Rantai GL TIDAK. | Melempar | Diameter Luar Laras. | Pin dia. | Kedalaman pelat | Perkiraan Muka Gigi pada Garis Pitch | Panjang Bantalan | Ketebalan Pelat | Kekuatan tarik pamungkas | Berat sekitar | |

| P | d1(maks) | d2(maks) | h2(maks) | b1(maks) | b2(maks) | S(maks) | Q | q | ||

| mm | mm | mm | mm | mm | mm | mm | kN | kg/kaki | kg/m | |

| WR-78XHD | 66,95 | 25.40 | 14.29 | 31,75 | 25.40 | 50.80 | 9.50 | 133,00 | 2.82 | 9.25 |

| WH-78XHD | 66,95 | 25.40 | 14.29 | 31,75 | 25.40 | 50.80 | 9.50 | 160,00 | 2.82 | 9.25 |

| WR-82XHD | 78.10 | 31,75 | 19.05 | 38.10 | 28.60 | 60,90 | 9.70 | 144,80 | 3.85 | 12.84 |

| WH-82XHD | 78.10 | 31,75 | 19.05 | 38.10 | 28.60 | 60,90 | 9.70 | 253,00 | 3.85 | 12.84 |

| WR-124XHD | 103.20 | 44.45 | 25.40 | 50.80 | 38.10 | 76.20 | 12.70 | 378,00 | 6.73 | 21.82 |

| WH-124XHD | 103.20 | 44.45 | 25.40 | 50.80 | 38.10 | 76.20 | 12.70 | 542,00 | 6.73 | 21.82 |

| WR-106XHD | 153,67 | 44.45 | 25.40 | 50.80 | 38.10 | 76.20 | 12.70 | 378,00 | 5.52 | 17.90 |

| WH-106XHD | 153,67 | 44.45 | 25.40 | 50.80 | 38.10 | 76.20 | 12.70 | 542,00 | 5.52 | 17.90 |

| WR-132XHD | 153,67 | 44.45 | 25.40 | 50.80 | 76.20 | 118.60 | 15,88 | 534,00 | 7.49 | 24.29 |

| WH-132XHD | 153,67 | 44.45 | 25.40 | 50.80 | 76.20 | 118.60 | 15,88 | 543,00 | 7.49 | 24.29 |

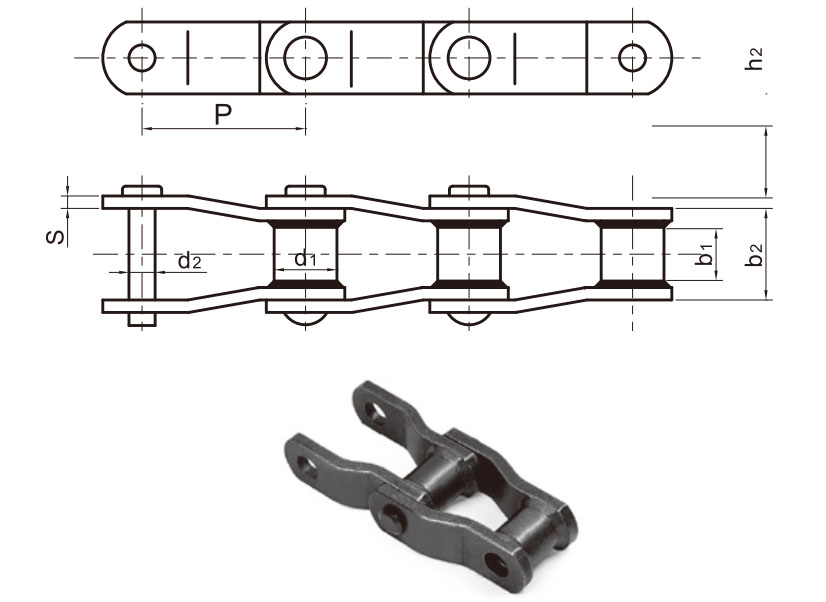

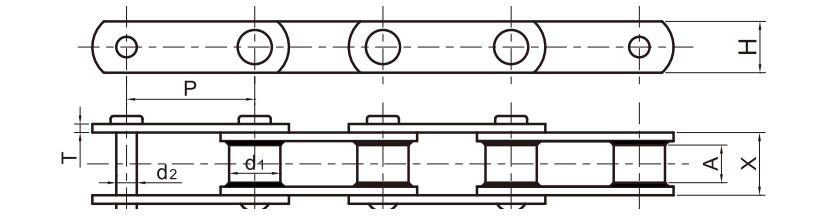

Rantai Penggilingan Baja Las Batang Lurus

| GL Nomor Rantai | Melempar | Diameter Luar Laras. | Pin dia. | Panjang Bantalan | Perkiraan Muka Gigi pada Garis Pitch | Kedalaman pelat | Ketebalan Pelat | Kekuatan tarik pamungkas | Berat sekitar | |

| P | d1(maks) | d2(maks) | X(menit) | A(maks) | H(maks) | T(maks) | Q | q | ||

| mm | mm | mm | mm | mm | mm | mm | kN | kg/kaki | kg/m | |

| WRC-78 | 66.27 | 21.336 | 12.70 | 50.80 | 25.40 | 31,75 | 6.35 | 120 | 1,95 | 6.40 |

| WRC-131 | 78.10 | 31,75 | 19.05 | 57.15 | 25.40 | 38.10 | 9.50 | 224 | 3.08 | 10.10 |

| WRC-124 | 101.60 | 31,75 | 19.05 | 71,00 | 38.10 | 38.10 | 9.50 | 224 | 3.62 | 11,88 |

| WRC-111 | 120,90 | 31,75 | 19.05 | 86.20 | 44.45. | 44.45 | 9.50 | 224 | 4.17 | 13.68 |

| WRC-110 | 152.40 | 31,75 | 19.05 | 86.20 | 38.10 | 38.10 | 9.70 | 224 | 3.26 | 10.70 |

| WRC-132 | 153,67 | 44.45 | 25.40 | 111,90 | 69,85 | 50.80 | 12.70 | 380 | 6.40 | pukul 21.00 |

| WRC-150 | 153,67 | 44.45 | 25.40 | 111,90 | 69,85 | 63.50 | 12.70 | 534 | 7.40 | 24.28 |

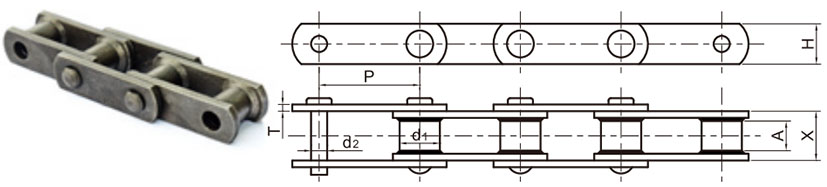

| Rantai GL No. | Melempar | Diameter Luar Laras. | Pin dia. | Panjang Bantalan | Perkiraan Muka Gigi pada Garis Pitch | Kedalaman pelat | Ketebalan Pelat | Kekuatan tarik pamungkas | Berat sekitar | |||||||||

| P | d1(maks) | d2(maks) | X(menit) | A(maks) | H(maks) | T(maks) | Q | q | ||||||||||

| mm | mm | mm | mm | mm | mm | mm | kN | kg/kaki | kg/m | |||||||||

| WRC-82XHD | 78.10 | 31,75 | 19.05 | 60.33 | 28.58 | 38.10 | 9.50 | 224 | 3.86 | 12.66 | ||||||||

| WRC-124XHD | 103.20 | 41.28 | 25.40 | 76.20 | 38.10 | 50.80 | 12.70 | 378 | 6.65 | 21.82 | ||||||||

| WRC-110XHD | 153,67 | 44.45 | 25.40 | 76.20 | 38.10 | 50.80 | 12.70 | 378 | 5.36 | 17.59 | ||||||||

| WRC-132XHD | 153,67 | 44.45 | 25.40 | 118.27 | 69,85 | 50.80 | 15,88 | 534 | 7.10 | 23.29 | ||||||||

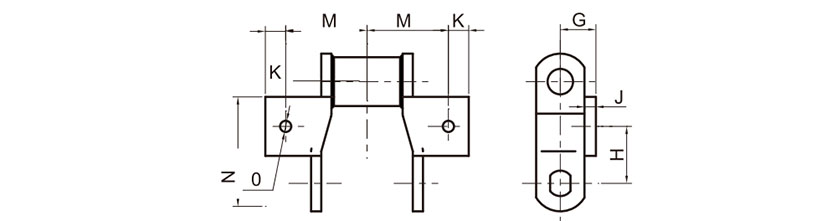

Lampiran untuk Rantai Penggilingan Baja Las

| Rantai GL No. | G | H | JK | M | N | 0 | ||||||||||

| mm | mm | mm | mm | mm | mm | mm | ||||||||||

| WR-78 | 22.23 | 31,75 | 6.35 | 12.70 | 50.80 | 31,75 | 9.53 | |||||||||

| WR-78XHD | 22.23 | 31,75 | 6.35 | 12.70 | 50.80 | 31,75 | 9.53 | |||||||||

| WR-82 | 22.23 | 38.10 | 6.35 | 15,88 | 60.33 | 44.45 | 9.53 | |||||||||

| WR-82XHD | 28.58 | 38.10 | 9.53 | 15,88 | 60.33 | 44.45 | 9.53 | |||||||||

| WR-124 | 28.58 | 50.80 | 9.53 | 15,88 | 66.66 | 44.45 | 9.53 | |||||||||

| WR-124XHD | 38.10 | 50.80 | 12.70 | 19.05 | 66.68 | 44.45 | 12.70 | |||||||||

| WR-111 | 31,75 | 53,98 | 9.53 | 15,88 | 79.38 | 44.45 | 9.53 | |||||||||

| WR-132 | 38.10 | 76.20 | 12.70 | 22.23 | 95.25 | 50.80 | 12.70 | |||||||||

| WR-132XHD | 38.10 | 76.20 | 12.70 | 22.23 | 95.25 | 50.80 | 12.70 | |||||||||

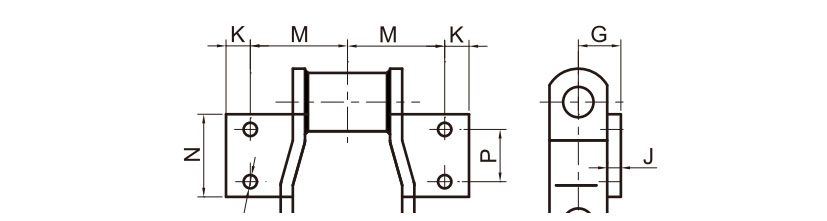

| Rantai GL TIDAK. | G | H | J | K | M | N | P | 0 |

| mm | mm | mm | mm | mm | mm | mm | mm | |

| WR-78 | 22.23 | 20.64 | 6.35 | 12.70 | 50.80 | 53,98 | 28.58 | 9.35 |

| WR-78XHD | 22.23 | 20.64 | 6.35 | 12.70 | 50.80 | 53,98 | 28.58 | 9.53 |

| WR-82 | 22.23 | 12.70 | 6.35 | 15,88 | 53,98 | 57.15 | 31,75 | 9.53 |

| WR-82XHD | 28.58 | 12.70 | 9.53 | 15,88 | 60.33 | 57.15 | 31,75 | 9.53 |

| WR-124 | 28.58 | 22.23 | 9.53 | 15,88 | 66.68 | 76.20 | 49.21 | 9.53 |

| WR-124XHD | 38.10 | 22.23 | 12.70 | 19.05 | 66.68 | 101.60 | 49.21 | 12.70 |

| WR-111 | 31,75 | 25.40 | 9.53 | 19.05 | 79.38 | 101.60 | 58.74 | 9.53 |

| WR-132 | 38.10 | 41.28 | 12.70 | 19.05 | 95.25 | 107,95 | 69,85 | 12.70 |

| WR-132XHD | 38.10 | 41.28 | 12.70 | 22.23 | 95.25 | 107,95 | 69,85 | 12.70 |

| WR-150 | 44.45 | 41.28 | 12.70 | 22.23 | 95.25 | 107,95 | 69,85 | 12.70 |

Rantai yang kami tawarkan ini unggul dalam kualitas, masa pakai, dan kekuatannya. Selain itu, rantai kami sangat tahan lama, mudah dirawat, dan ditawarkan dengan harga terjangkau! Keunggulan rantai ini adalah setiap komponennya telah melalui proses perlakuan panas dan dibuat menggunakan paduan baja berkualitas tinggi untuk meningkatkan masa pakai dan kekuatan rantai secara keseluruhan. Rantai baja las ini sering direkomendasikan untuk sebagian besar aplikasi pengangkutan, penggerak, dan pengangkatan yang membutuhkan rantai tanpa rol baja berkekuatan tinggi dan tahan lama. Beberapa aplikasi yang paling umum menggunakan rantai ini antara lain konveyor tugas berat, produk kehutanan, penanganan biji-bijian, pulp dan kertas, serta pengolahan gula.